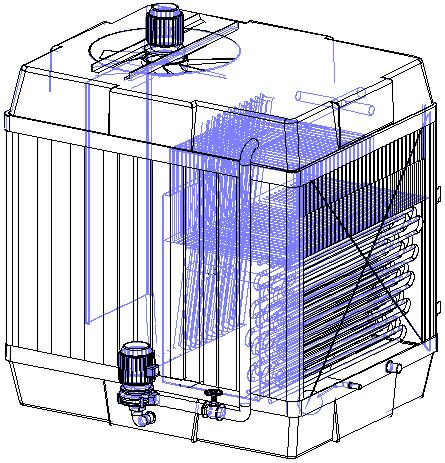

EVAPORATIVE COOLERS AND CONDENSERS IN CLOSED CIRCUIT: |

CD / RF SERIES |

ADVANTAGES OF OUR COOLERS: |

|

ü The

fluid does not enter in contact with atmosphere;

üEquipment

is shipped assembled or half-assembled to suit standard 20' dry or 40'HC

containers;

üOptimized

heat transfer exchange;

üEasy access to all components;

üBuilt in corrosion-resistant materials. üHydrostatic

pipe Test at 750 PSI ( 52.8 Kgf/cm2). |

Click on the pictures below to ENLARGE.

ADDITIONAL INFORMATION:

Fluid

Coolers are very similar to cooling towers. They both reject heat by evaporating water and

use many of the same components; except for the coil bundles used in coolers in place of

some or all of the wet deck used in cooling towers.

Coil

products can be described such as:

- Closed

circuit cooling towers (fluid coolers) used to cool fluids or,

-

Evaporative Condensers that condense refrigerant.

Closed

circuit towers typically produce the same result as the “open” cooling tower-

that of cooling a water stream from an elevated temperature to a reduced temperature-

although other fluids can also be cooled. The fluid in the process is confined within a

coil inside the fluid cooler. Heat is passed through the walls of numerous coil circuits

to water, which is sprayed over the coil. The process fluid remains free of contamination

while the water on the exterior sacrifices itself to evaporating and collecting debris

from the air stream.

The water

from the basin is drained by a small pump, mounted on the outside of the fluid cooler and it

is conveyed to the top of the cooler where it is sprayed over the coil.

The

closed circuit tower is ideal for cooling equipment with small, hard to clean passageways

that would clog with a conventional cooling tower. The quality of the water is preserved

in closed circuit. Therefore the closed circuit cooler costs appreciably more to purchase

and operate. In addition to that, the physical size of the cooler is always bigger than

that of a cooling tower, sized for the same duty.

Coils

are usually manufactured in HDGS (hot dipped galvanized steel), depending on the fluid and plant

conditions. Closed

circuit cooling towers should not be

applied to systems that have open pipes. An open system causes corrosion of the

untreated coil interior or incrustation, reducing heat transfer and causing premature coil failure.

Acid water can also ruin coils in very short term.

Another

type of fluid cooler is the evaporative condenser. It is built like a fluid cooler but

instead of sensible temperature reduction of a liquid stream, it accepts a gas (such as

compressor discharge in a refrigeration system) and extracts latent heat causing the

gas

to condense.

For

additional information, please contact our engineering department.

© 2001 HD Equipamentos Industriais Ltda. All rights reserved.

FOR FURTHER INFORMATION, PLEASE CALL (55-11) 3531.6199

- E-MAIL: hd@hd.ind.br